No. Plateau honing refers to a surface-finish outcome (removing sharp peaks while preserving valleys for oil retention), not the mechanism of stone actuation like “double expansion.” It’s typically achieved by a multi-step finishing sequence (rough hone to establish cross‑hatch, then a lighter “plateau” pass or brush/ball‑hone to truncate peaks), whereas “double expansion” describes a tool design/feeding method, not the texture goal.

What plateau honing means

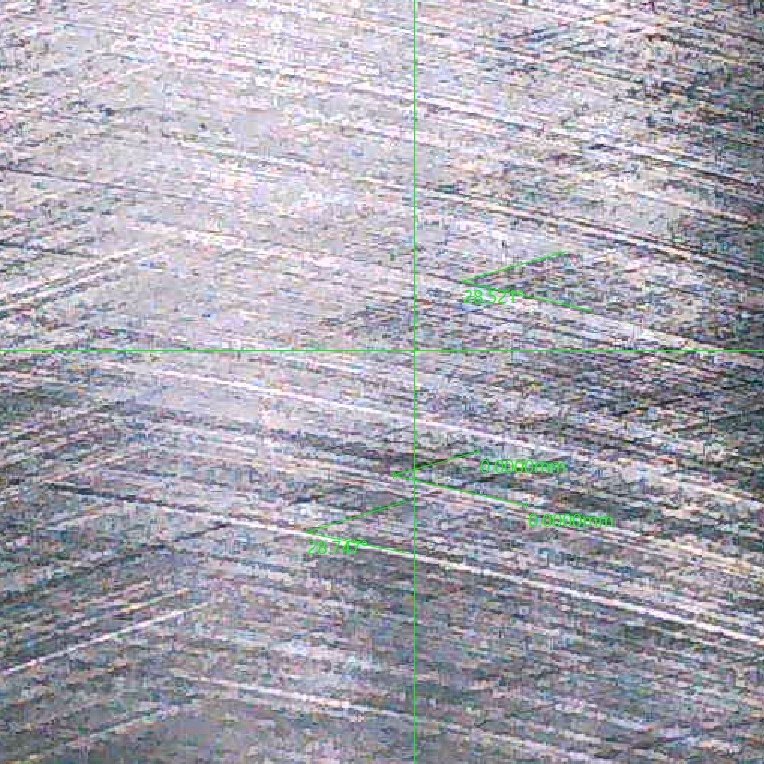

• Plateau honing produces an “engineered surface” with flattened peaks and retained valleys, improving lubrication, ring seating, and reducing break‑in debris in bores such as engine cylinders. This is a process/finish concept, independent of how the stones are expanded.

• It is commonly implemented as rough honing followed by a finer plateauing step (or with brush/ball-style tools), specifically to increase bearing area while maintaining oil-holding valleys.

What double expansion means

• Double expansion refers to a honing head behavior where stones can be expanded from multiple mechanisms or in multiple stages (e.g., coarse then fine), a feature of the tooling/feed system. It does not inherently define the final texture as “plateau.”

• A shop can use double-expansion tooling to perform plateau honing, but the plateau finish depends on the sequence, abrasives, and parameters—not on the mere fact of double expansion.

Practical takeaway

• If the goal is a plateau finish, specify the finish requirement (e.g., cross‑hatch angle, Ra/Rz, Rpk/Rk/Rvk, and plateauing step) rather than a tool actuation term like double expansion.

So next time some one says you need double expansion tool to achieve plateau honing surface , feel free to show them this post.