For spring‑energized PTFE seals, specify a very smooth, non‑lead mating surface in the 2–16 µin RMS band, adjusted to medium and temperature: cryogenic liquids/gases at 2–4 RMS, non‑cryogenic gases at 6–12 RMS, and liquids at 8–16 RMS. This window minimizes wear and leakage while still allowing a PTFE transfer film to form; going rougher raises wear and leak paths, while mirror‑like finishes can hinder film formation in some services.

Key requirements

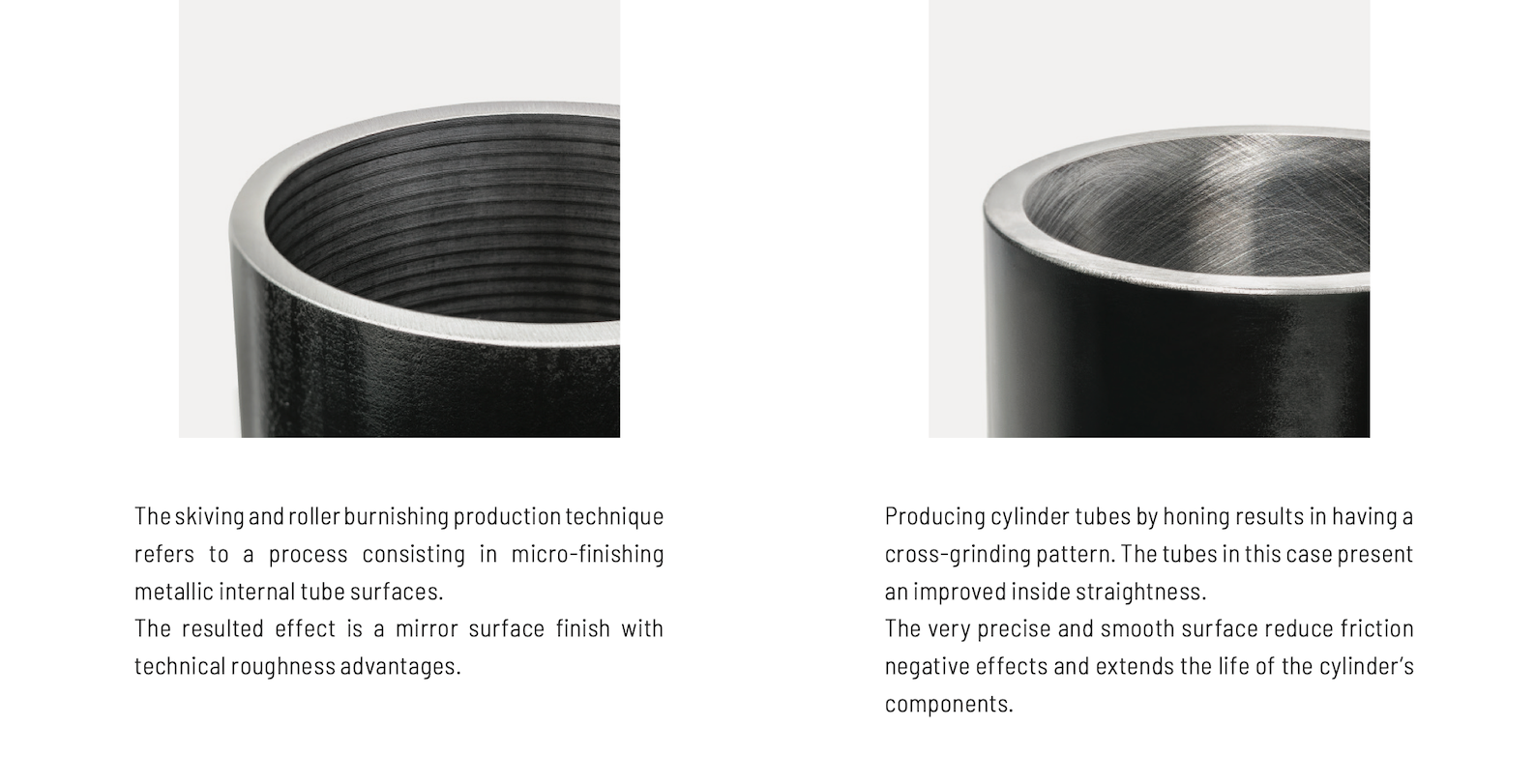

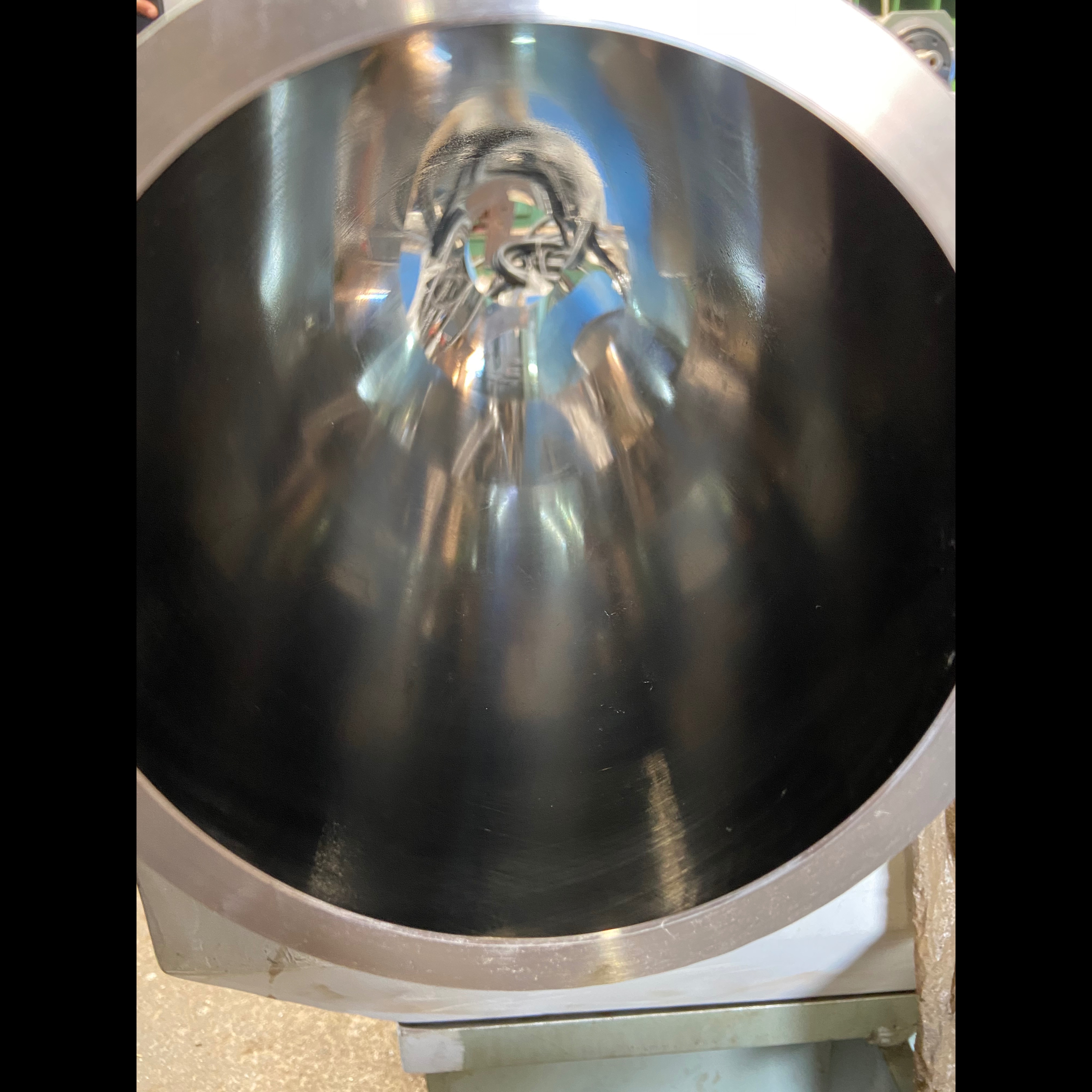

• No lead finish: Use plunge‑ground or non‑helical finishing so the surface has no spiral lead that can pump fluid under the seal. This becomes more critical as surfaces approach polished RMS levels.

• Hardness and coatings: Ensure adequate counterface hardness to resist adhesion and wear; hard chrome, electroless nickel, and nitriding are commonly used to pair with polished finishes for PTFE jackets.

Verification and tolerances

• Document both RMS (or Ra equivalents) and finishing method on prints, referencing the application band above; supplier tables show cryogens needing the lowest RMS, gases mid‑range, and liquids the highest.

• Inspect with profilometry and confirm finish over the full contact track; reduce scratches and tool marks that create leakage paths even if the average RMS is in spec.

Quick reference

• Dynamic band: 2–16 RMS overall; choose sub‑ranges by medium (cryogen 2–4, gases 6–12, liquids 8–16).

• Rationale: Smoother finishes reduce friction and wear; controlled smoothness still supports transfer film and leak‑tight performance.