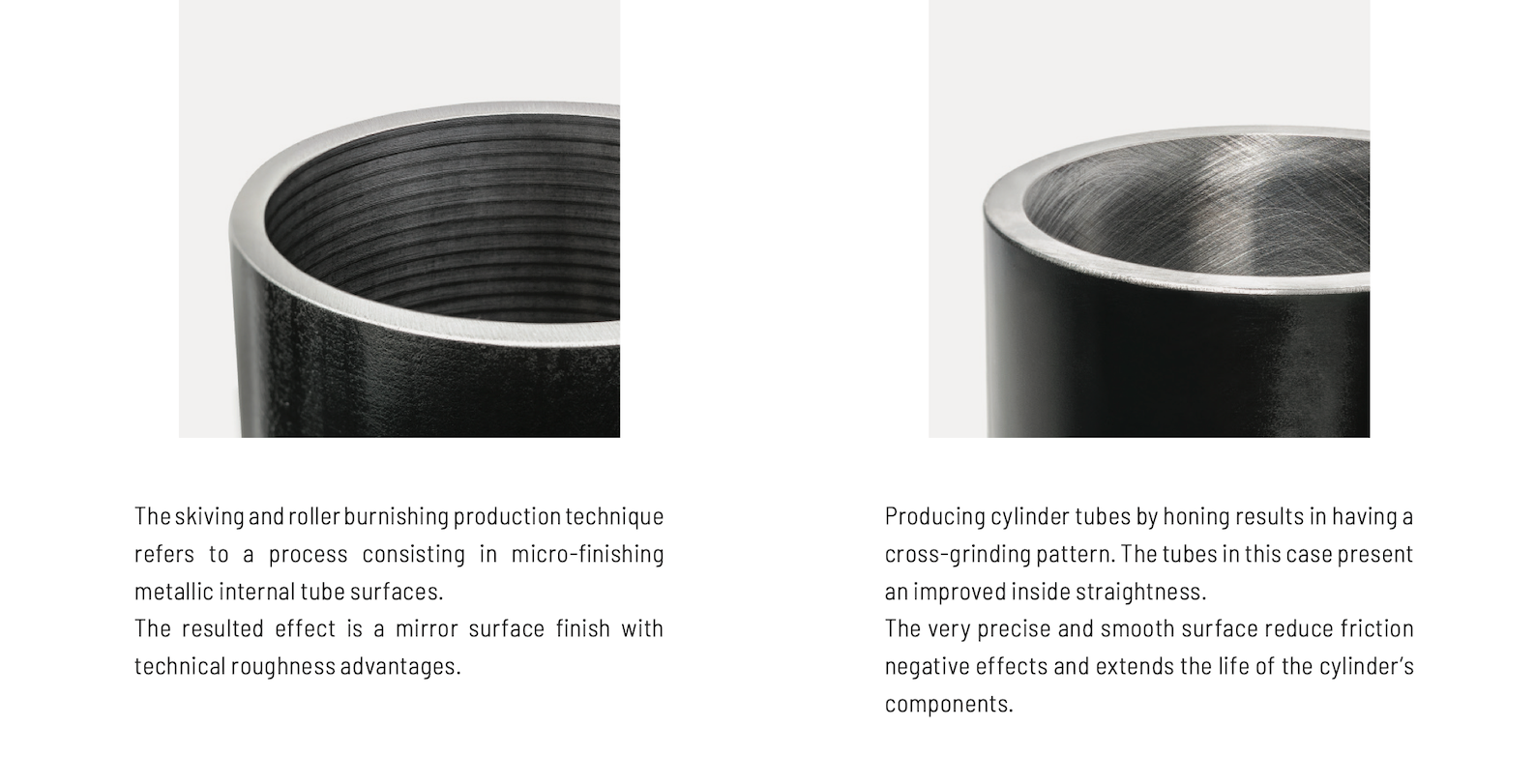

Some seals are compatible with very smooth, even polished surfaces, but many dynamic elastomer lips prefer a lightly textured, plateau-honed finish that retains micro-lubricant; PTFE-based seals typically tolerate and even benefit from smoother, polished shafts within a defined roughness window, whereas standard rubber O-rings and elastomer lips can leak or wear on mirror-polished surfaces lacking valleys.

PTFE and spring-energized PTFE

• PTFE rotary/reciprocating seals generally work best on smooth, polished shafts in the range of about 2–16 RMS depending on medium and temperature, with liquids commonly 8–16 RMS and non-cryogenic gases 6–16 RMS; at cryogenic temperatures, 2–4 RMS is advised. Excessively rough surfaces abrade PTFE, while overly mirror finishes inhibit transfer film formation.

• Avoid helical machining lead on polished shafts, as spiral grooves can pump fluid and cause leakage; plunge grinding or non-lead polishing is preferred even when the target finish is highly smooth.

Elastomer O-rings and lip seals

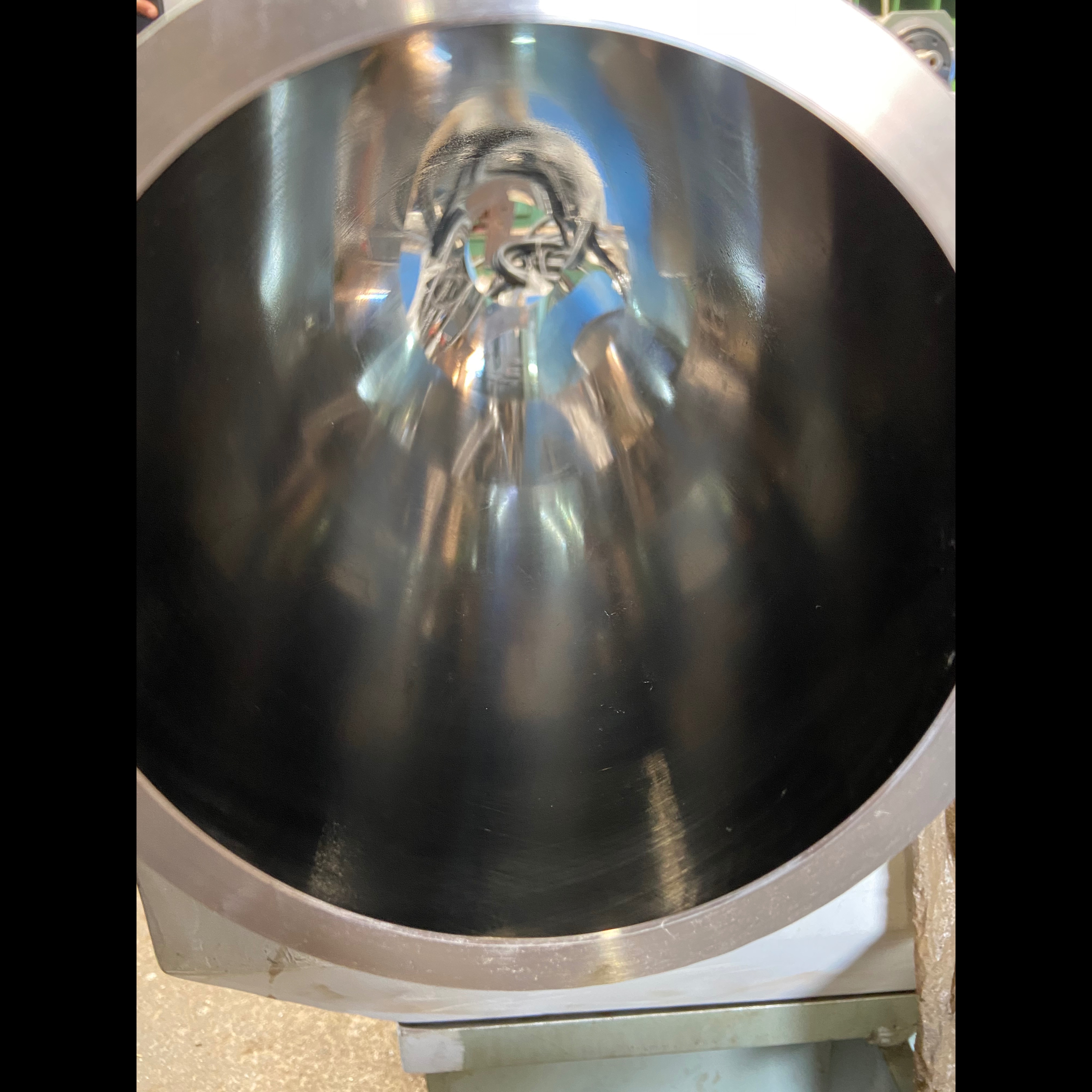

• Elastomeric seals are compliant and tolerate rougher surfaces, but for dynamic service a highly polished counterface is not ideal because it won’t hold lubricant; typical guidance favors about 10–20 µin RMS for reciprocating, with honed/burnished or hard-chrome plated finishes that present micro-pockets.

• For static glands, smoother is beneficial up to about 32 µin RMS for liquids and 16 µin RMS for vacuum/gases, but dynamic elastomer lips need some texture to reduce frictional heat and avoid starvation.

“Polished” compatibility summary

• Compatible: PTFE and spring-energized PTFE seals on shafts polished within their recommended RMS window and with non-leaded texture; these designs rely on a thin transfer film and can exhibit low leakage at very low Ra/RMS values.

• Caution: Standard NBR/FKM elastomer lips on mirror-polished, valley-free surfaces may see increased leakage/wear due to poor lubricant retention; a plateau-honed or burnished finish is usually better for leakage control.

• Mixed cases: Some rotary elastomer lips for light oils may run on finely polished 16 RMS shafts, but results depend on lubrication regime and hardness; confirm with the seal supplier’s finish band.

Practical guidance

• Specify finish by RMS/Ra and “no lead” rather than just “polished, ” and include Rk parameters if leakage is critical; PTFE often calls for 2–16 RMS, elastomer lips for reciprocating around 10–20 µin RMS with plateau texture.

• If leakage rises after aggressive polishing, reintroduce plateau by light honing or micro-matting to restore valleys while staying within the seal maker’s window.