What are the advantages of Honing over skiving and burnishing in hydraulic cylinders?

Honing is considered important in extending the life of hydraulic cylinders as compared to skiving and burnishing for several reasons:

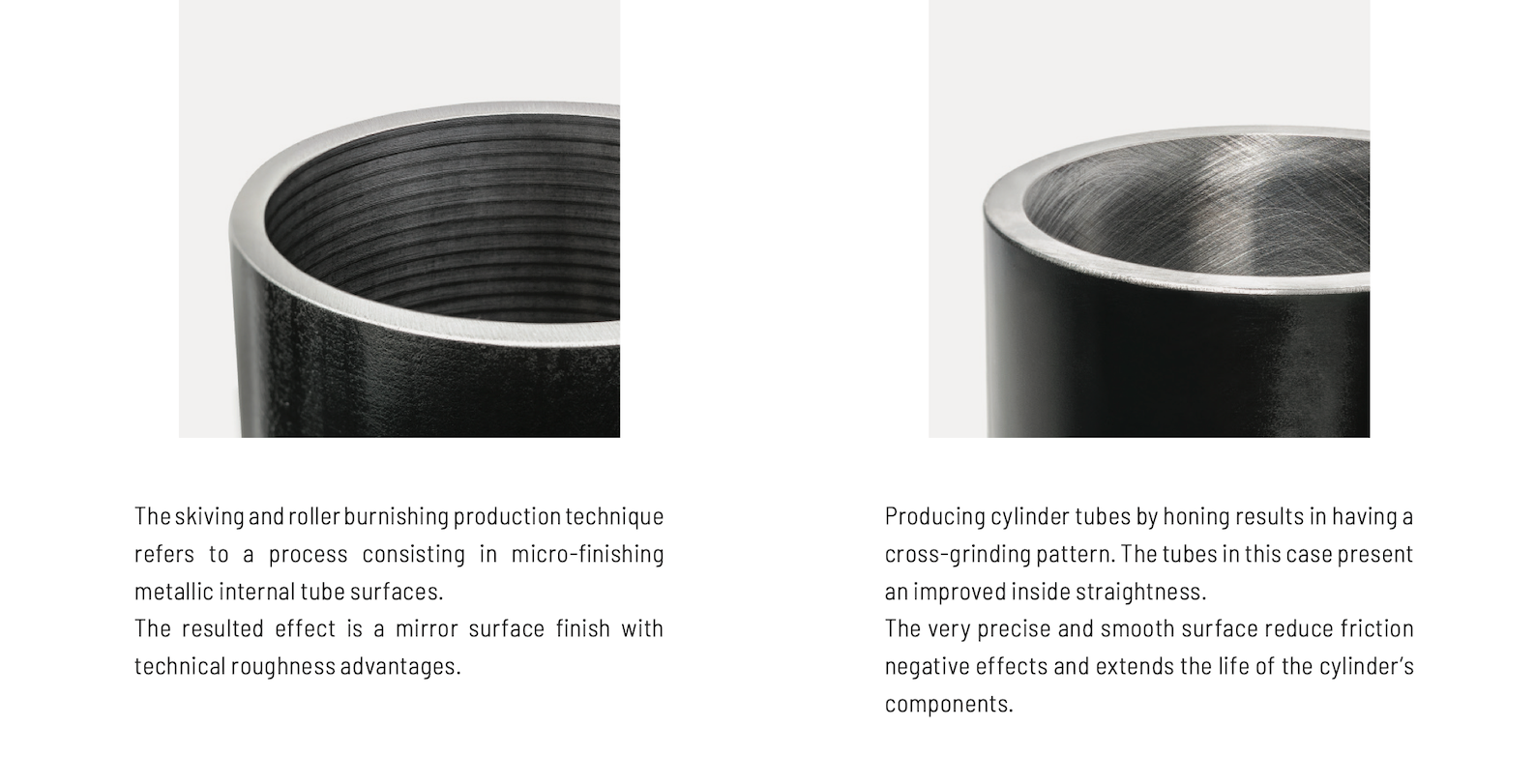

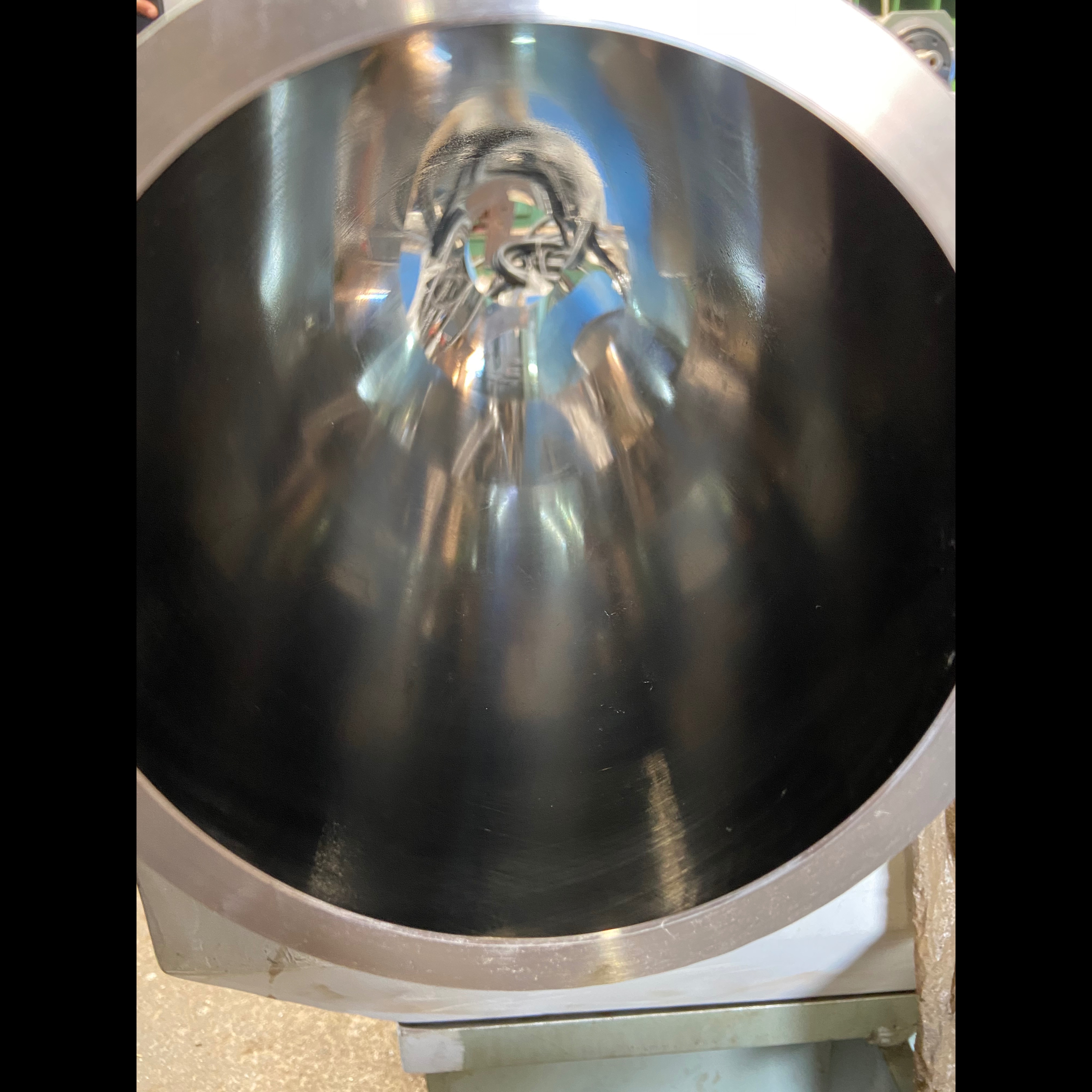

1. Surface Finish: Honing produces a smoother, more uniform surface finish on the inner diameter of the cylinder bore. This reduces friction between the cylinder and piston, leading to a reduction in wear and tear and a longer life for the cylinder and seals.

2. Tolerance Control: Honing provides precise control over bore geometry, including diameter, roundness, and cylindricity. This tight tolerance control ensures proper fit between the piston and cylinder, reducing friction and increasing the life of the cylinder and seals.

3. Geometry Correction: Honing can correct out-of-round or out-of-straight bores, which can cause problems with cylinder function and lead to premature failure.

4. Material Removal: Honing removes only a small amount of material, reducing the risk of altering the bore geometry and damaging the cylinder. Skiving and burnishing, on the other hand, remove more material and can cause excessive thinning of the cylinder wall, reducing its strength and leading to failure.

In conclusion, honing is a more precise and gentle machining process that is better suited to the needs of hydraulic cylinders. By providing a smooth surface finish, tight tolerance control, and geometry correction, honing helps extend the life of hydraulic cylinders and their seals.

Keywords

1.

tear

risk

wear

needs

seals

Honing

piston

skiving

problems

friction

strength

roundness

reduction

other hand

advantages

conclusion

proper fit

longer life

cylindricity

small amount

cylinder wall

cylinder bore

bore geometry

inner diameter

straight bores

precise control

several reasons

Material Removal

cylinder function

premature failure

excessive thinning

Geometry Correction

hydraulic cylinders

smooth surface finish

tight tolerance control

gentle machining process

smoother, more uniform surface finish