"Maximizing Engine Performance with Gear Inner Diameter Honing"

Gear inner diameter honing is a critical process in maximizing engine performance and longevity. In this blog, we will explore the importance of honing, what it involves, and how to achieve the best results for optimized search engine performance.

What is Gear Inner Diameter Honing?

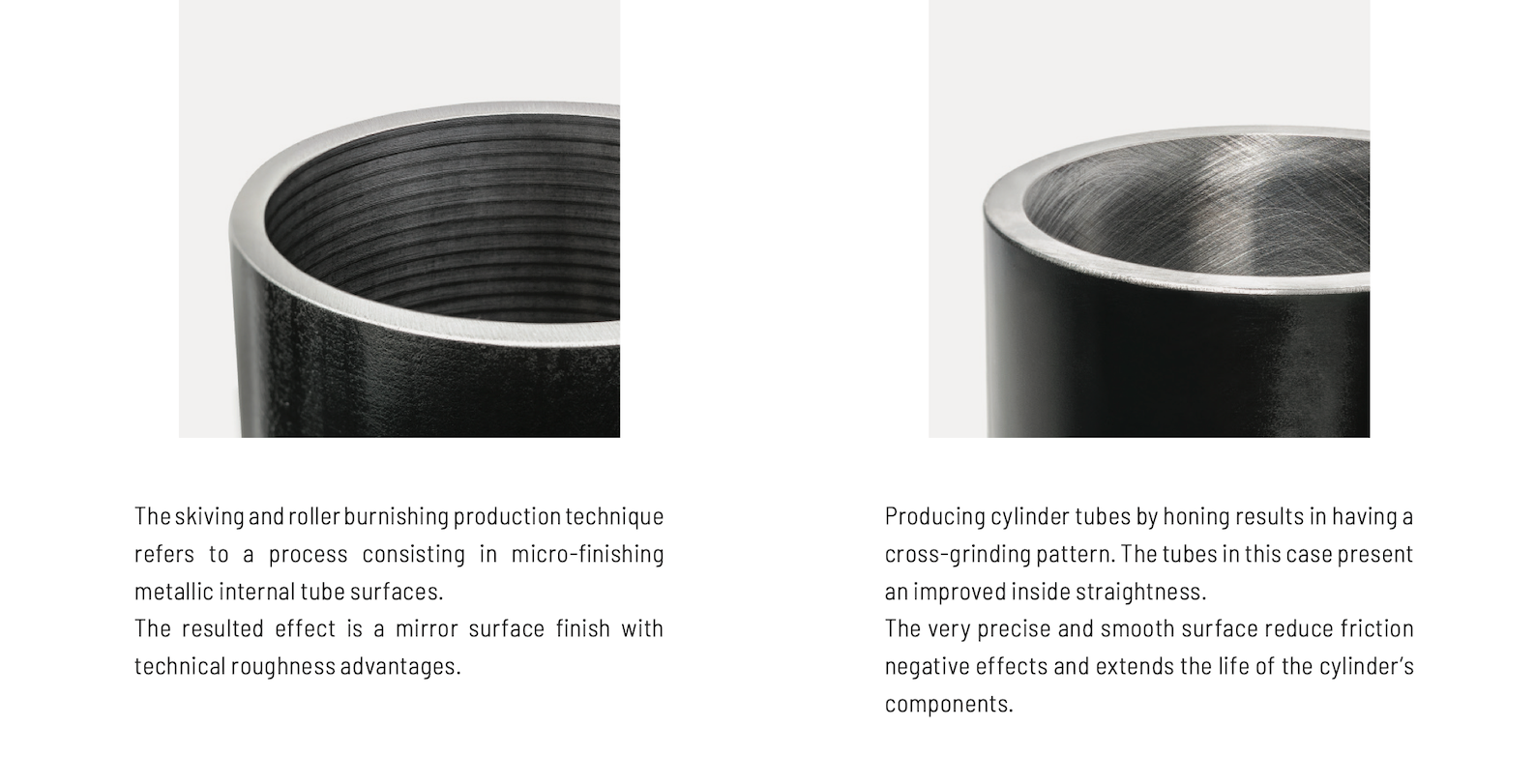

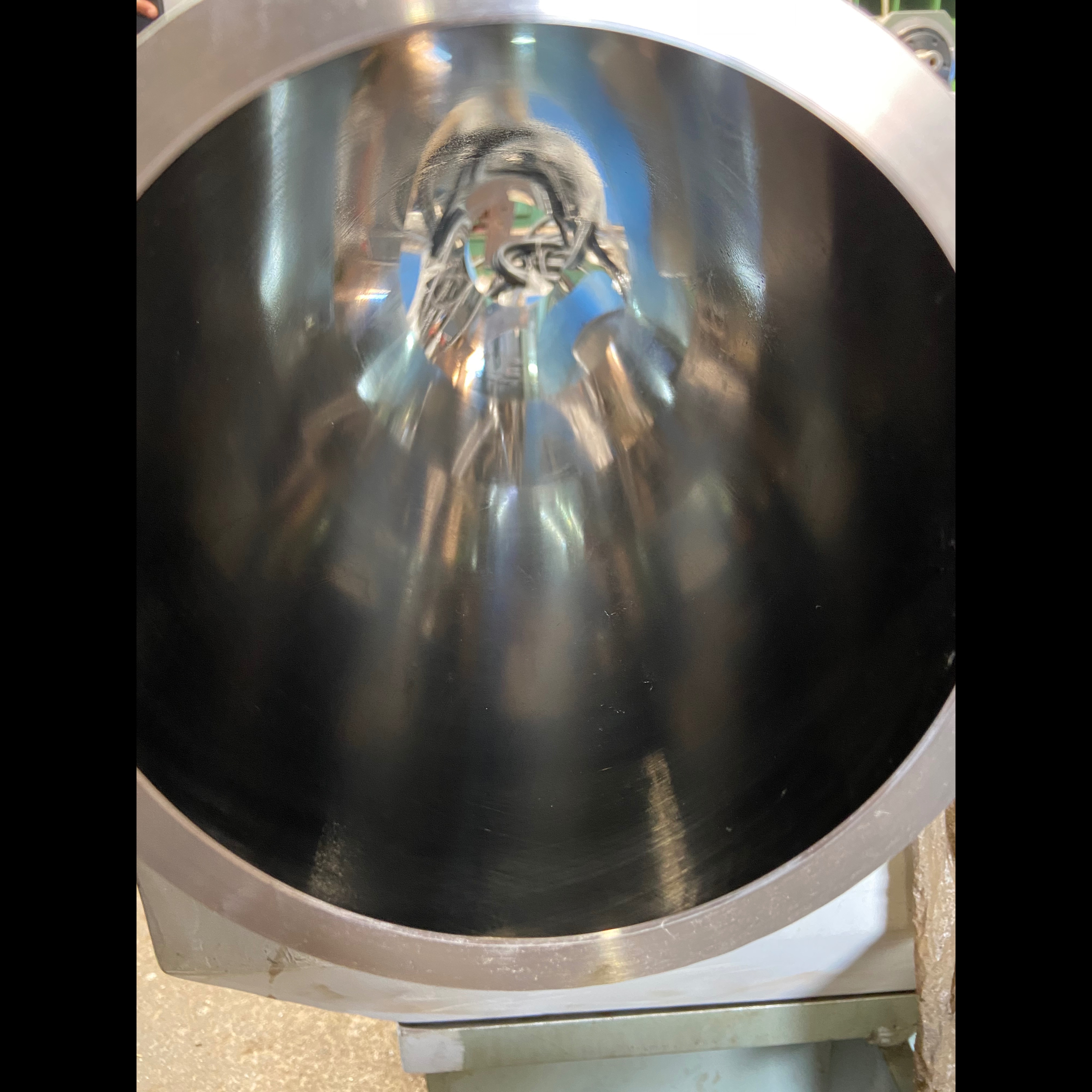

Honing is a precision machining process that involves using a honing tool to achieve a smooth, precise inner diameter surface on a gear. This process is necessary to ensure a proper fit between the gears and shafts, and to minimize friction, noise, and wear in the transmission system.

Why is Honing Important?

Accurate inner diameter measurements are crucial for ensuring proper gear meshing, which is critical for effective power transfer and longevity of the engine components. Honing also improves surface finish and roundness, which reduces friction and wear between gears. This, in turn, increases the life of the gears and reduces the risk of engine failure.

How to Achieve the Best Results

To achieve the best results with gear inner diameter honing, it is essential to follow best practices, including:

Proper tool selection: Choose the right honing tool for the job based on the material, geometry, and size of the gears.

Precision measurements: Use precision measuring tools, such as micrometers and dial indicators, to ensure accurate inner diameter measurements.

Consistent speed and feed rates: Maintain consistent speed and feed rates during the honing process to achieve a consistent, uniform surface finish.

Regular maintenance: Regularly inspect and maintain honing tools to ensure optimal performance and accuracy.

By following these best practices, you can achieve the best results with gear inner diameter honing and maximize the performance and longevity of your engine components.

Conclusion

Gear inner diameter honing is a critical process in maximizing engine performance and longevity. Proper honing techniques, tool selection, and maintenance are essential to achieving the best results. By implementing these best practices, you can ensure your engine runs smoothly and efficiently for many years to come

Keywords

job

turn

blog

size

wear

risk

life

noise

gears

shafts

material

geometry

friction

accuracy

roundness

longevity

many years

feed rates

Conclusion

proper fit

importance

micrometers

best results

honing tools

engine failure

honing process

best practices

dial indicators

critical process

Consistent speed

right honing tool

engine components

transmission system

optimal performance

proper gear meshing

Regular maintenance

Proper tool selection

Precision measurements

Proper honing techniques

effective power transfer

search engine performance

precision measuring tools

Gear inner diameter honing

precision machining process

Maximizing Engine Performance

consistent, uniform surface finish

Accurate inner diameter measurements

smooth, precise inner diameter surface