How can one avoid uneven scoring marks while honing cylinder?

Uneven scoring marks can be avoided while honing a cylinder by following these steps:

Select the right abrasive: Choose an abrasive that is well-suited for the material of the cylinder being honed. Abrasive selection should consider factors such as the hardness and composition of the material, as well as the desired surface finish. Talk to u to know the right stone for your job

Control honing parameters: Honing parameters such as speed, pressure, and tool orientation can have a significant impact on the surface finish of the honed cylinder. Ensure that these parameters are well-controlled and optimized for the specific honing operation.

Monitor tool wear: Over time, the honing tool will wear, and its performance will decline. Regular monitoring of tool wear will ensure that worn tools are replaced before they cause uneven scoring marks.

Use honing fluid: Honing fluid can help to reduce friction and heat during the honing process, resulting in a more uniform and consistent surface finish. Ensure that an appropriate honing fluid is used and that it is applied in the correct manner.

Use proper honing techniques: Proper honing techniques, such as maintaining consistent pressure and avoiding excessive vibration, can help to minimize uneven scoring marks.

By following these steps, one can significantly reduce the occurrence of uneven scoring marks while honing a cylinder and achieve a more consistent and uniform surface finish.

Keywords

job

heat

time

tools

steps

speed

factors

material

friction

hardness

composition

honing tool

performance

right stone

honing process

correct manner

right abrasive

honed cylinder

tool orientation

Monitor tool wear

significant impact

Regular monitoring

Abrasive selection

excessive vibration

consistent pressure

uneven scoring marks

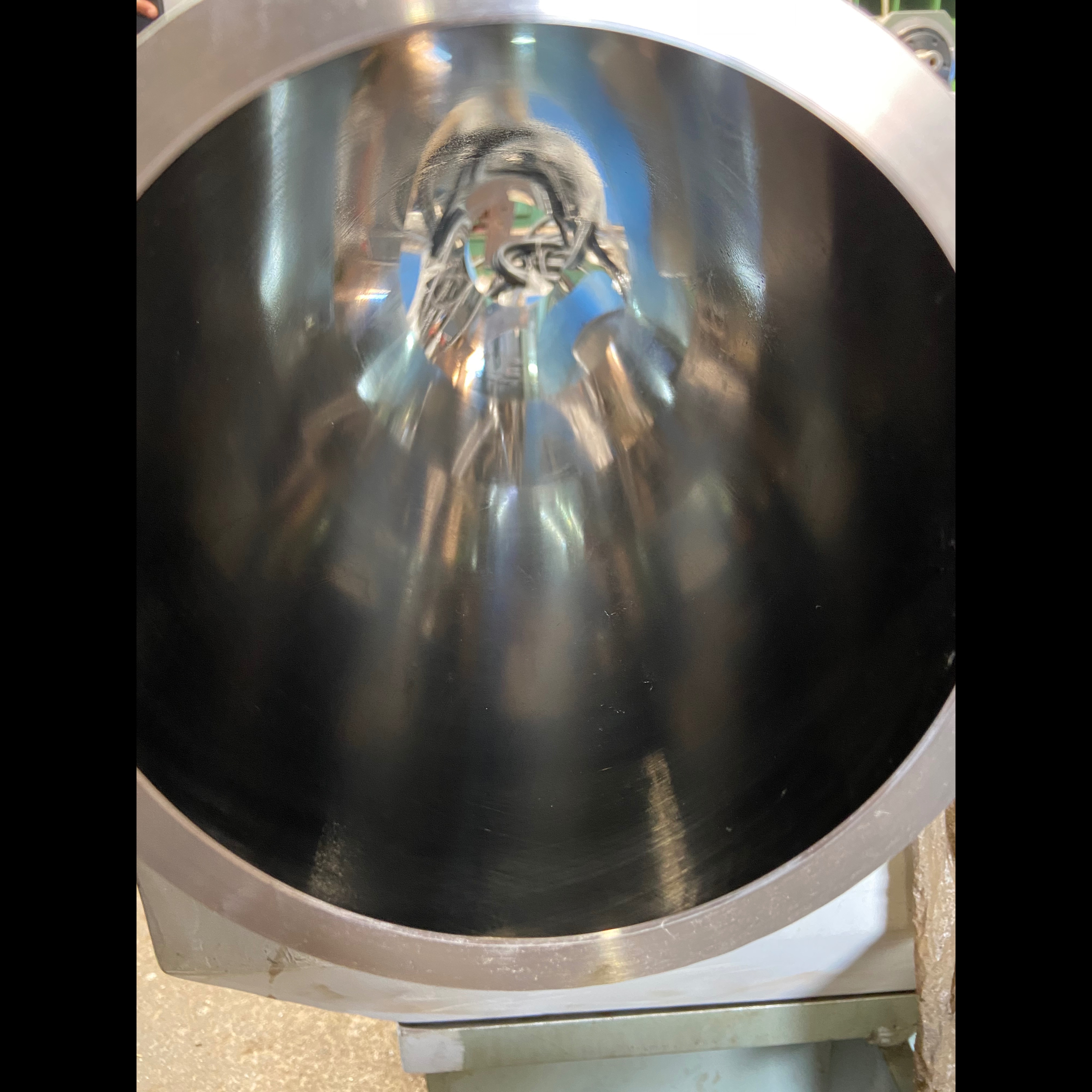

uniform surface finish

appropriate honing fluid

proper honing techniques

consistent surface finish

Control honing parameters

specific honing operation