Honing Job of the Day: Reconditioned Tailstock of Our 3mtr Lathe

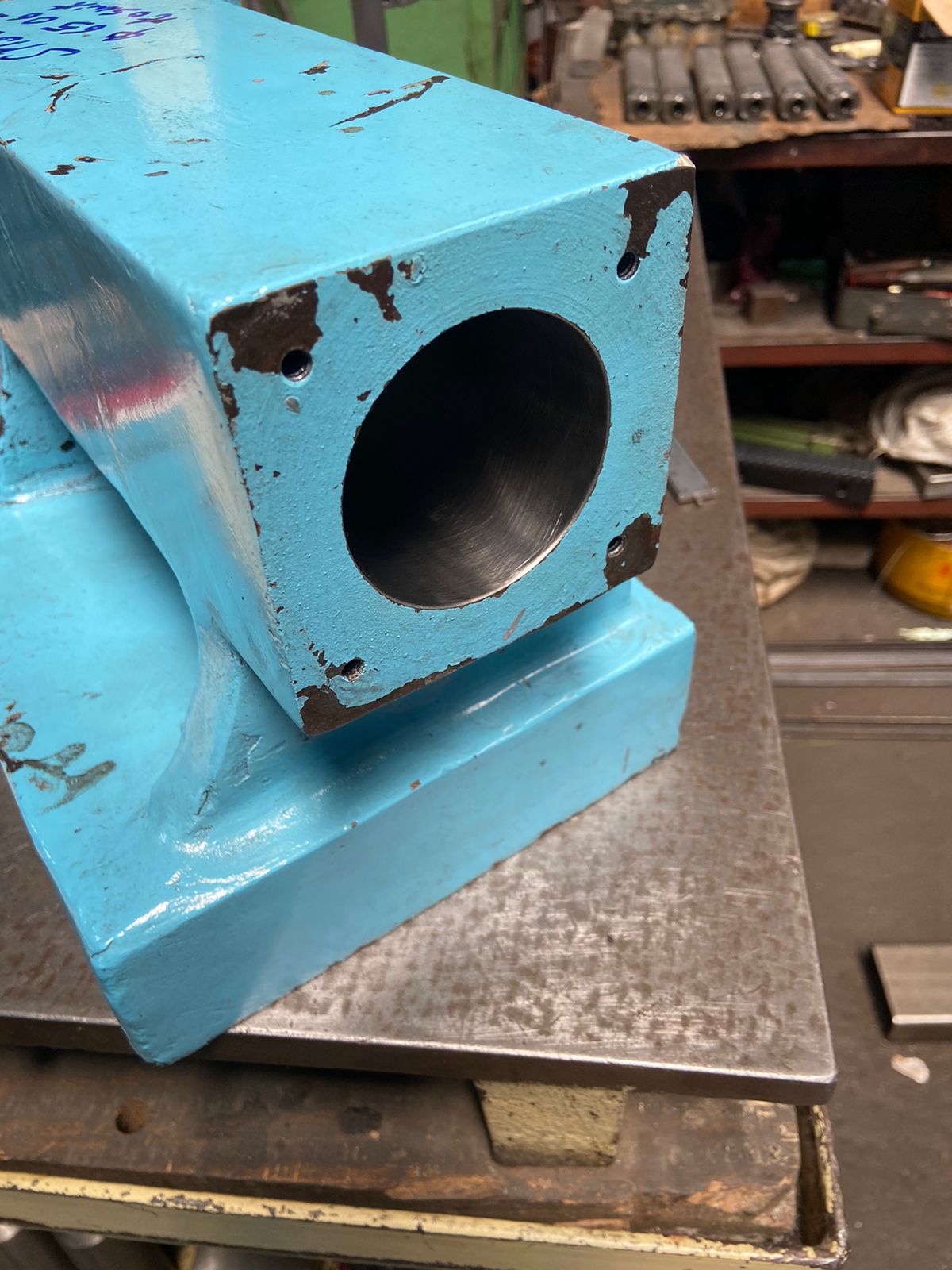

At our facility, we take pride in the precision and quality of our Honing services. We recently had an interesting job at our workshop that we wanted to share with our readers. It involved the reconditioning of the tailstock of our 3mtr lathe, and we are excited to share the details of the Honing process we employed to achieve perfection.

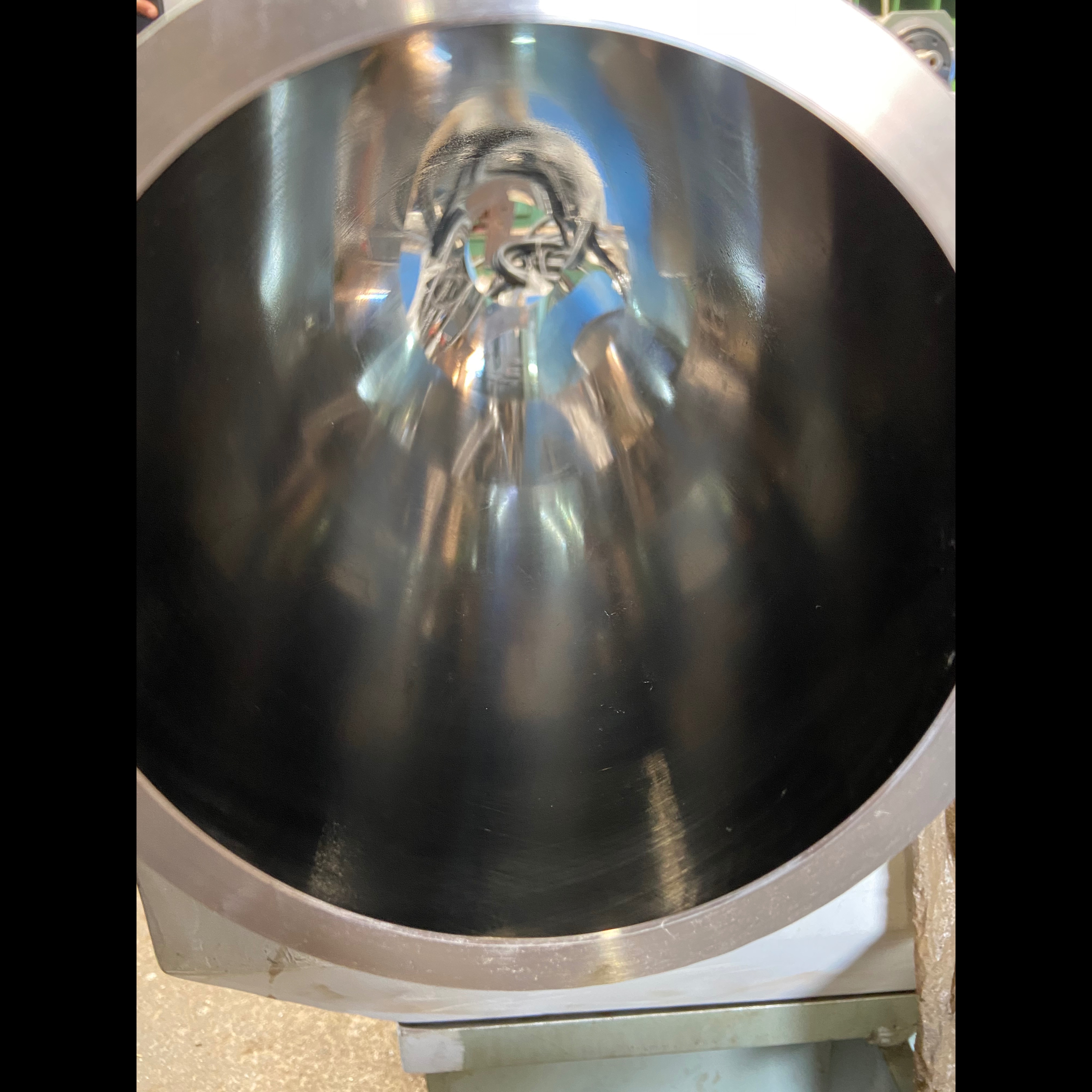

After the scrapping process was completed on the lathe, we noticed that the bed height had reduced, which meant that the tailstock had to be rebored. Our team of experts decided to use honing to ensure the perfection of the bore with straightness and ovality control and to ensure the perfect sliding of the tailstock in the housing.

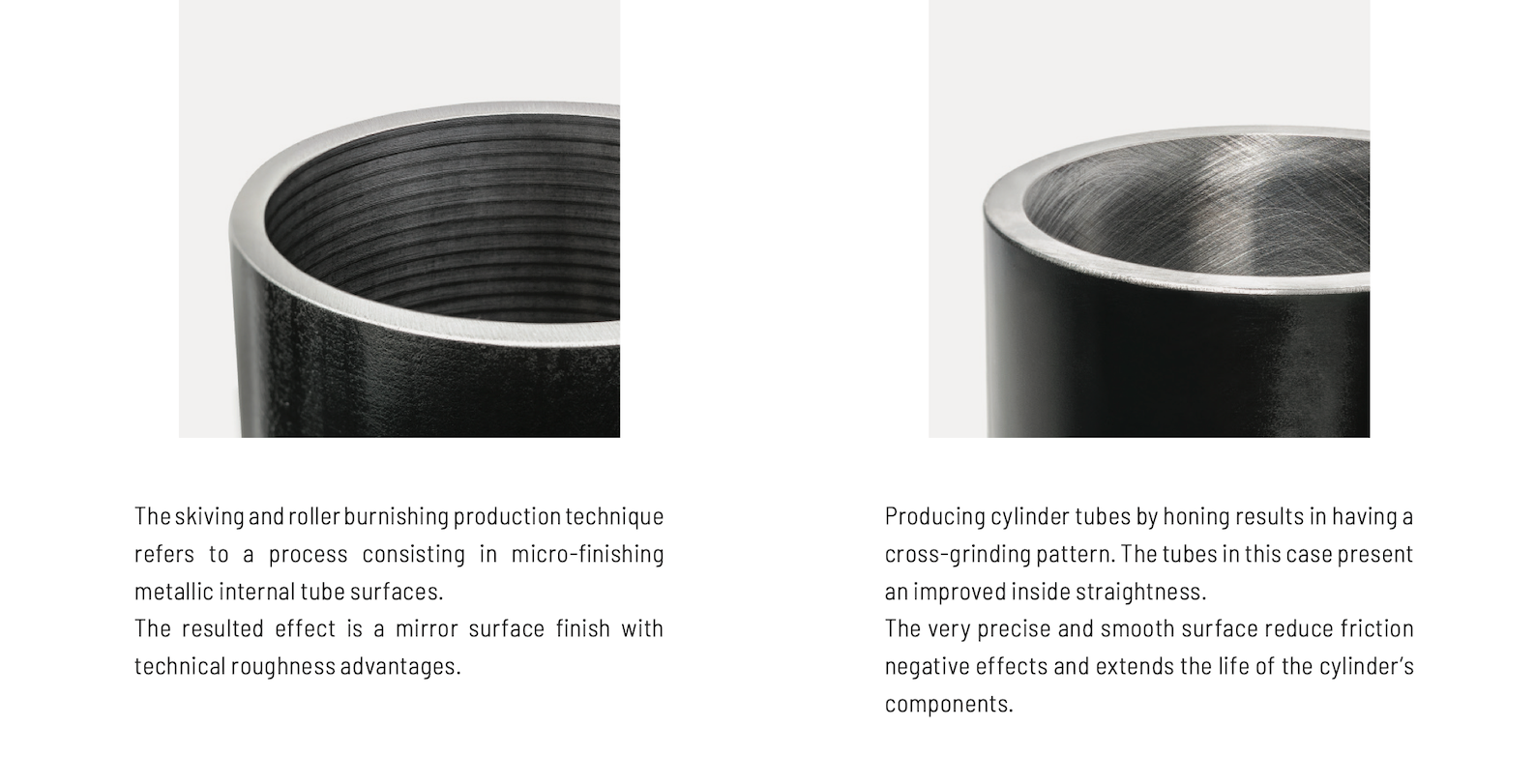

The Cast iron housing had an Ovality of close to 0.6mm, which was not acceptable for the required tolerances. Our team used a 220-grit SiliconCarbide type stone to hone the housing. The honing process involved using abrasive stones to remove small amounts of material from the surface of the housing. This process helped us to achieve the desired surface finish and tolerances.

We later polished the bore with 320-grit emery paper, which helped us to achieve an Ra value of 0.3 microns Roughness. We ensured that the ovality and Taper of the bore were achieved well within 10 microns for the total length of 300mm. This was crucial to ensure that the tailstock could slide smoothly in the housing and meet the desired tolerances.

At our facility, we trial our Machines with different types of jobs, including difficult to hone jobs. Most of our customers consult us about these challenging jobs, and we share all such incidents and job stories relevant to honing, hoping they might be useful to our readers even in the future.

In conclusion, Honing is a critical process that helps us achieve the desired tolerances and surface finish for various machine components. The Honing job of the day, the reconditioned tailstock of our 3mtr Lathe, is an excellent example of how we use honing to ensure precision and quality in our work. We hope this article has been informative and useful to our readers, and we look forward to sharing more honing job stories in the future.

Keywords

Day

bore

team

300mm

Taper

0.6mm

pride

future

experts

details

readers

quality

article

workshop

Ra value

material

Machines

facility

required

incidents

Tailstock

precision

customers

10 microns

conclusion

3mtr Lathe

bed height

perfection

straightness

total length

small amounts

surface finish

Honing process

reconditioning

interesting job

perfect sliding

different types

ovality control

Honing services

abrasive stones

critical process

challenging jobs

excellent example

scrapping process

desired tolerances

honing job stories

320-grit emery paper

0.3 microns Roughness

The Cast iron housing

various machine components

220-grit SiliconCarbide type stone