Gear ID Honing ?

When it comes to manufacturing gears for the automotive industry, achieving high levels of precision is critical for optimal performance. In particular, the internal diameter of the gear must be honed to a high degree of accuracy and surface finish. While grinding is a common technique for honing, the thin wall thickness of the gear often poses a challenge for internal grinding machines.

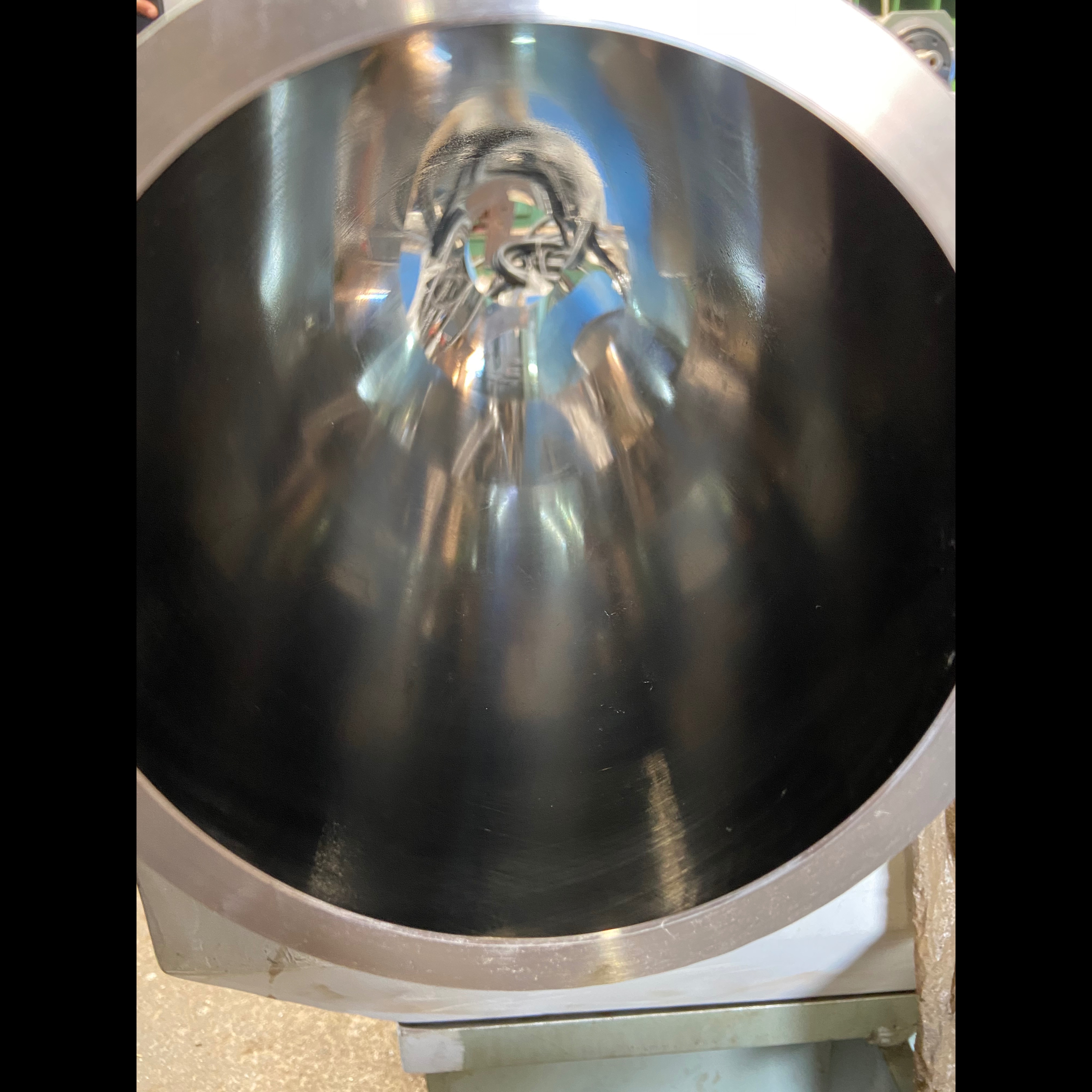

Enter the Schnell hone 250, a honing machine specifically designed for small bores such as those found in gears manufactured using powder metallurgy techniques. At our company, we have found that the Schnell hone 250 is the best solution for honing the internal diameter of gears to achieve the required surface roughness of up to Ra0.2.

With the Schnell hone 250, we are able to achieve very close tolerances of about 15 microns in 60 mm bore, and excellent Ra value finishes. This means that our customers can be confident in the precision of their gears, leading to improved performance and reliability in the final product.

At our company, we are dedicated to providing our customers with the best possible solutions for their honing needs. If you are facing challenges in honing the internal diameter of gears or other components, please don't hesitate to reach out to us. We would be more than happy to help you find the right solution for your specific needs.

In conclusion, the Schnell hone 250 is an excellent solution for honing the internal diameter of gears used in the automotive industry. With its ability to achieve high levels of precision and surface finish in small bores, the Schnell hone 250 is a valuable tool for manufacturers looking to produce high-quality gears.

Keywords

company

accuracy

customers

challenge

precision

15 microns

60 mm bore

conclusion

high degree

reliability

high levels

small bores

Schnell hone

honing needs

final product

valuable tool

best solution

manufacturers

surface finish

honing machine

right solution

specific needs

other components

close tolerances

common technique

surface roughness

internal diameter

high-quality gears

excellent solution

optimal performance

manufacturing gears

automotive industry

thin wall thickness

improved performance

best possible solutions

internal grinding machines

excellent Ra value finishes

powder metallurgy techniques