Advancing Cylinder Honing: Introducing Automatic Taper Removal (ATR) with the VHM 1500 Intelli Series Honing Machine Manufactured by Krishna Machine Tools in Bangalore

Problem Statement: Tackling the Taper Challenge in Cylinder Honing with Krishna Machine Tools' VHM 1500 Intelli Series Honing Machine

Achieving consistent and precise results in cylinder honing is vital for industries like automotive, aerospace, and hydraulic manufacturing. One of the most complex aspects faced by professionals is dealing with taper, particularly in the middle section of the bore. Traditional methods heavily rely on operator expertise, leading to variations and increased manual labor. Recognizing this challenge, Krishna Machine Tools, a leading honing machine manufacturer based in Bangalore, introduces the VHM 1500 Intelli Series Honing Machine with Automatic Taper Removal (ATR) technology, a groundbreaking innovation that transforms the honing process.

Introducing ATR: Automating Taper Removal

Designed and manufactured by Krishna Machine Tools, the VHM 1500 Intelli Series Honing Machine incorporates the revolutionary ATR technology, redefining the way taper correction is achieved in honing operations. ATR is an intelligent system that enables the machine to automatically detect and remove taper within the cylinder bore, eliminating the need for manual adjustments and minimizing operator-dependent processes. This breakthrough innovation significantly enhances precision, consistency, and efficiency in cylinder honing operations.

How ATR Works: Automation at Its Finest

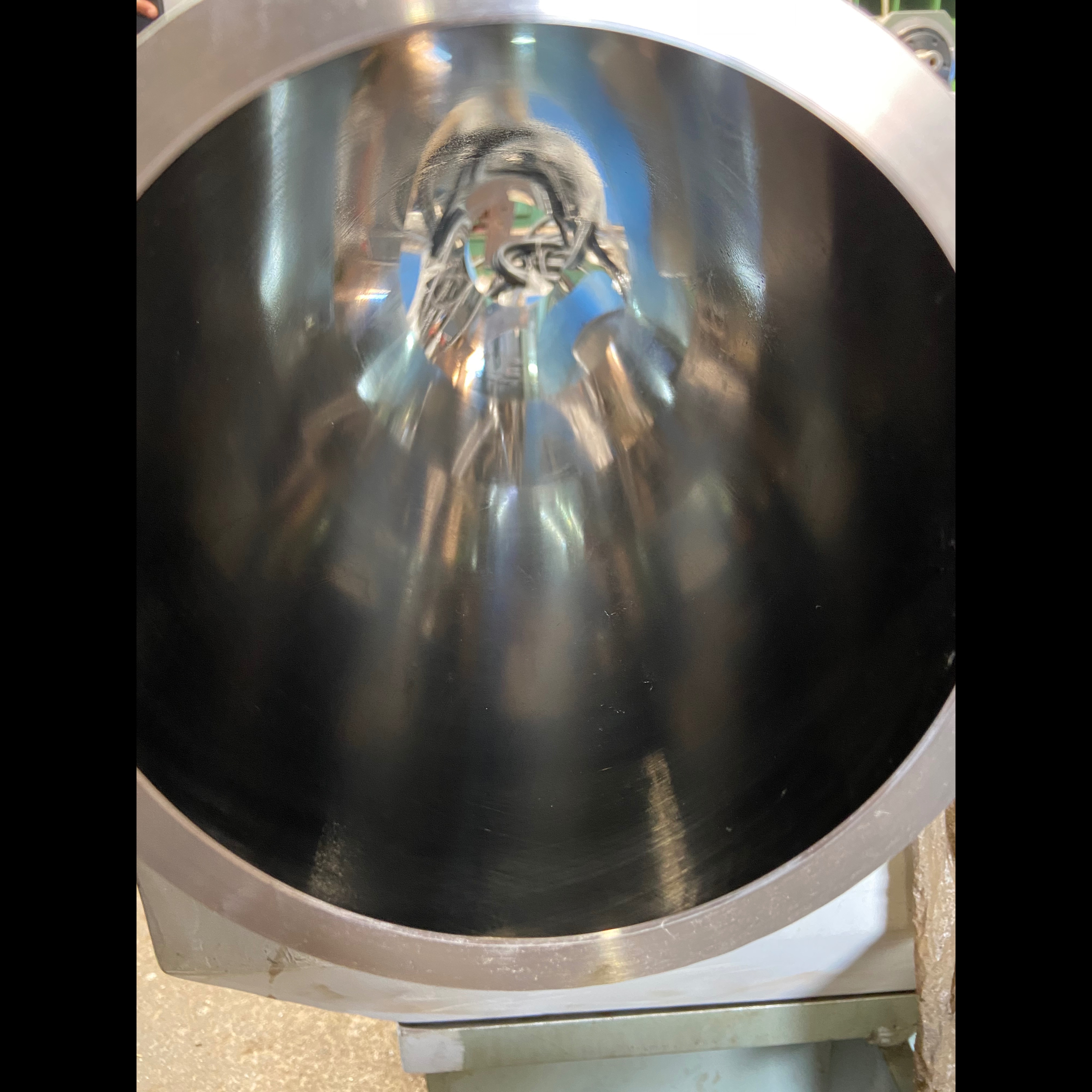

ATR empowers the VHM 1500 Intelli Series Honing Machine to take honing to new heights. Equipped with advanced sensors and intelligent algorithms, the machine detects the taper within the bore and automatically adjusts the honing parameters to correct it precisely. The result is a bore with a flawlessly straight profile and minimal taper variation, guaranteeing optimal performance and prolonged lifespan of the honed components.

Benefits of ATR Technology

Unparalleled Precision: ATR technology eradicates the inconsistencies associated with manual taper correction, ensuring a uniform taper removal process and achieving superior bore accuracy.

Enhanced Efficiency: By automating the taper removal process, the VHM 1500 Intelli Series machine significantly reduces operator dependency, saving time and effort while boosting overall productivity.

Cost Savings: With ATR technology, companies can reduce labor costs and minimize rework caused by human error, optimizing their honing operations and maximizing profitability.

Experience the Future of Honing with Krishna Machine Tools

Krishna Machine Tools, a trusted name in the industry, remains committed to pushing the boundaries of honing technology. The VHM 1500 Intelli Series Honing Machine with ATR is a testament to this commitment. This groundbreaking advancement offers the industry a reliable, efficient, and automated solution to overcome the challenges associated with taper removal in cylinder honing.

Discover the power of ATR technology and experience the unmatched precision and efficiency it brings to your honing processes. Contact Krishna Machine Tools today to learn more about the VHM 1500 Intelli Series Honing Machine and explore how it can transform your honing operations.

Note: This blog provides an overview of ATR technology and its benefits, showcasing the advanced honing machine manufactured by Krishna Machine Tools in Bangalore. For detailed technical specifications and further information, please reach out to our dedicated team of experts.

Keywords

way

time

blog

Note

need

power

Finest

effort

rework

Future

experts

Benefits

industry

overview

companies

testament

aerospace

boundaries

consistent

industries

automotive

challenges

Automation

commitment

variations

consistency

information

human error

new heights

labor costs

Cost Savings

trusted name

manual labor

professionals

cylinder bore

profitability

dedicated team

middle section

honing process

precise results

inconsistencies

complex aspects

ATR) technology

Taper Challenge

advanced sensors

honed components

straight profile

honing technology

honing parameters

operator expertise

prolonged lifespan

intelligent system

manual adjustments

automated solution

operator dependency

unmatched precision

Enhanced Efficiency

Traditional methods

optimal performance

overall productivity

Unparalleled Precision

superior bore accuracy

intelligent algorithms

minimal taper variation

advanced honing machine

Automatic Taper Removal

breakthrough innovation

hydraulic manufacturing

manual taper correction

groundbreaking innovation

groundbreaking advancement

cylinder honing operations

Bangalore Problem Statement

revolutionary ATR technology

operator-dependent processes

uniform taper removal process

Contact Krishna Machine Tools

VHM 1500 Intelli Series machine

detailed technical specifications

leading honing machine manufacturer

The VHM 1500 Intelli Series Honing Machine

Krishna Machine Tools' VHM 1500 Intelli Series Honing Machine