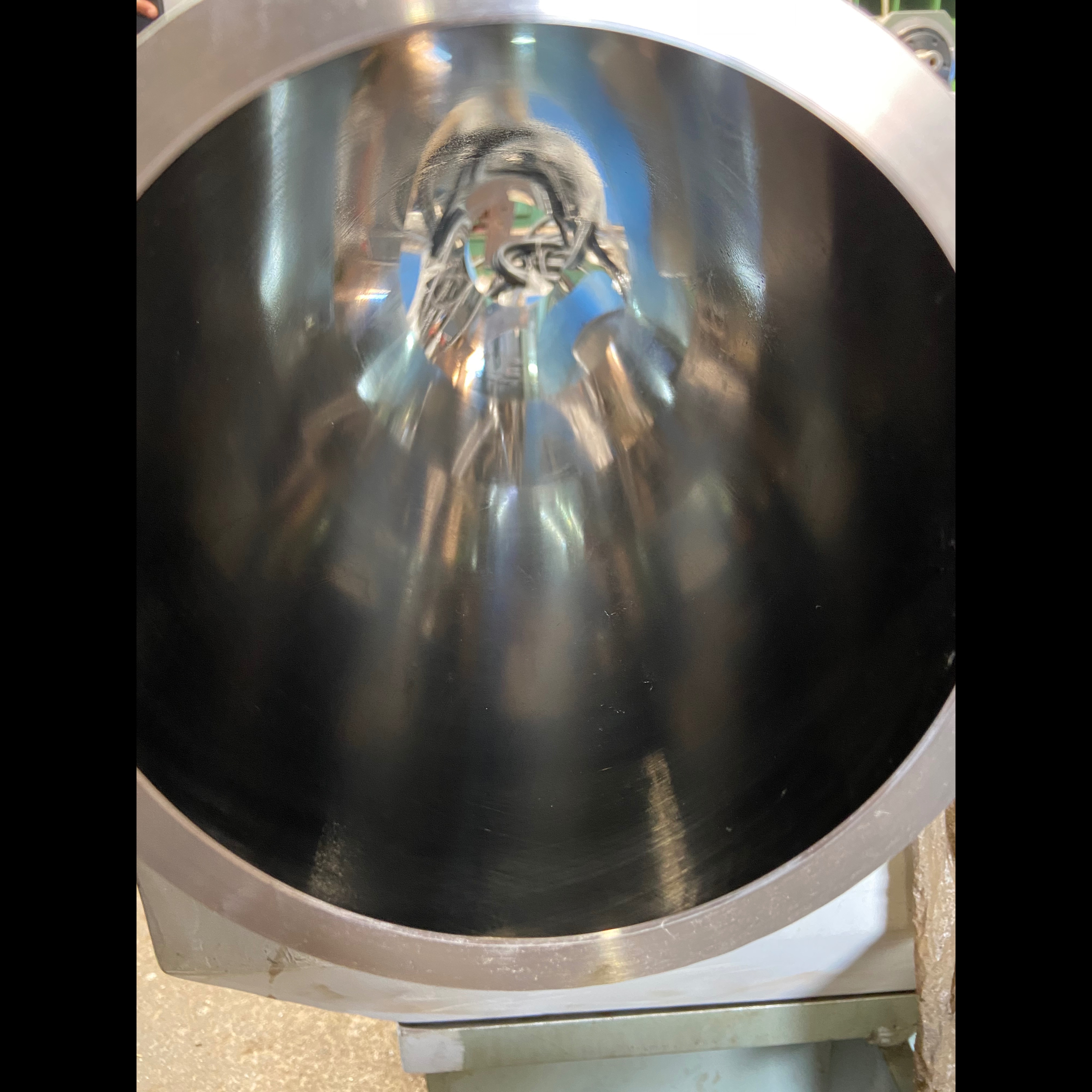

Achieving Precision Results in Honing Stepped Bores with VHM Series Honing Machines and KMG Series Honing Heads

Honing stepped bores can be a challenging task, especially when it comes to maintaining the concentricity of the bores. This is especially important when honing is done after heat treatment and the component is hardened to about 46 HRC. At this point, even the slightest error in the honing process can lead to component failure, resulting in a significant loss of time and money.

To overcome this challenge, we at Krishna Machine Tools have developed a unique solution – our VHM series honing machines, paired with KMG series honing heads. These tools are specially designed to achieve precise results while honing stepped bores, ensuring consistency and accuracy throughout the process.

The VHM series honing machine is equipped with a hydraulic expansion system that allows the honing head to expand uniformly, providing a constant pressure against the bore walls. This, combined with the KMG series honing heads, which are specially designed to maintain concentricity throughout the entire honing process, makes our honing solution one of the best in the market.

In addition to the hydraulic expansion system, our VHM series honing machines are also equipped with manual expansion tools. These tools allow the stone to hold a constant position, preventing any striking when the tool enters into a step inside the bore of the component. This ensures that the component is honed uniformly, providing a consistent finish every time.

At Krishna Machine Tools, we understand the importance of precision and accuracy in the honing process. That's why our VHM series honing machines and KMG series honing heads are designed to deliver superior results, even in the most challenging situations. If you're facing any issues in honing stepped bores, feel free to get in touch with us. Our team of experts will be happy to assist you in finding the right solution for your specific needs.

Keywords

team

time

touch

stone

money

point

issues

market

46 HRC

experts

striking

addition

accuracy

challenge

importance

bore walls

consistency

concentricity

Stepped Bores

right solution

specific needs

heat treatment

Honing stepped

honing solution

slightest error

precise results

unique solution

challenging task

significant loss

superior results

constant position

component failure

consistent finish

Precision Results

constant pressure

entire honing process

challenging situations

manual expansion tools

KMG Series Honing Heads

At Krishna Machine Tools

hydraulic expansion system

VHM Series Honing Machines

The VHM series honing machine