Achieving Precision and Efficiency in Honing 35mm Hydraulic Cylinder Tubes

Introduction:

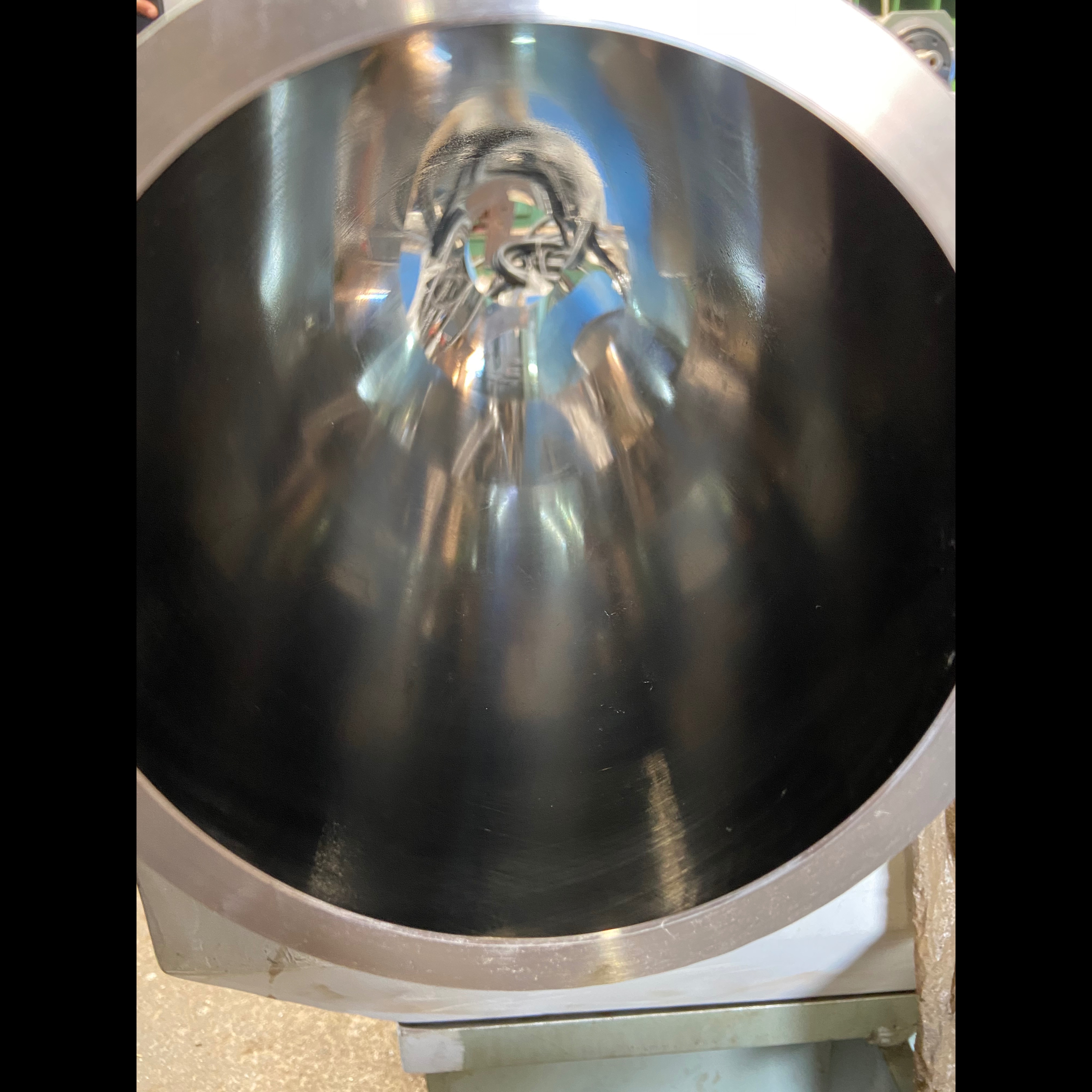

When it comes to honing hydraulic cylinder tubes with a diameter of 35mm and a length of 600mm, several challenges arise due to the nature of the bore. Boring irregularities, roughness, and inaccuracies can hinder the honing process, leading to increased stone wear and reduced efficiency. However, with the advent of advanced honing technology, such as our VHM 1000 machine, these challenges can be overcome, ensuring faster material removal, improved precision, and enhanced productivity.

Challenges of Honing 35mm Hydraulic Cylinder Tubes:

The long bore length of 600mm poses unique challenges during the honing process. Boring irregularities, such as taper and roughness, often occur, affecting the overall quality and functionality of the cylinder tubes. Additionally, boring inaccuracies can result in uneven material removal, leading to accelerated wear of honing stones and increased manufacturing lead time.

The Solution: VHM 1000 Honing Machine

Our VHM 1000 honing machine is designed to address the specific challenges encountered when honing 35mm hydraulic cylinder tubes. This advanced machine offers innovative features that streamline the honing process and deliver exceptional results.

Auto Clamping and Hydraulic Expansion:

The VHM 1000 features an auto clamping mechanism and hydraulic expansion, ensuring secure and precise clamping of the cylinder tubes. This eliminates any movement or vibrations during the honing process, resulting in a superior surface finish and reduced irregularities.

In-Process Taper Removal:

One of the key advantages of the VHM 1000 is its advanced in-process taper removal option. This feature allows operators to easily remove tapers and irregularities while honing, ensuring a consistent and precise bore throughout the entire length of the cylinder tube. By eliminating taper-related issues, the VHM 1000 significantly reduces rejections and improves overall productivity.

Efficient Material Removal and Waste Reduction:

The VHM 1000 enables faster material removal, thanks to its high-speed honing capability and optimized cutting parameters. This ensures efficient honing of the 35mm cylinder tubes, reducing manufacturing lead time and improving productivity. Additionally, the advanced design of the machine minimizes stone wastage, resulting in cost savings and enhanced operational efficiency.

Conclusion:

Honing 35mm hydraulic cylinder tubes over a length of 600mm can present significant challenges due to boring irregularities, roughness, and inaccuracies. However, with the VHM 1000 honing machine, these obstacles are effectively overcome. The machine's auto clamping, hydraulic expansion, in-process taper removal, and efficient material removal capabilities make it an ideal choice for high-volume production. By utilizing the VHM 1000, manufacturers can achieve precision, reduce lead time, improve productivity, and deliver high-quality hydraulic cylinder tubes to meet the demands of various industries.

Keywords

600mm

nature

tapers

advent

secure

demands

diameter

improved

movement

Precision

roughness

operators

obstacles

vibrations

consistent

rejections

Conclusion

stone wear

The Solution

Introduction

ideal choice

cost savings

precise bore

The VHM 1000

entire length

manufacturers

functionality

stone wastage

honing stones

key advantages

honing process

Waste Reduction

overall quality

advanced design

efficient honing

accelerated wear

advanced machine

VHM 1000 machine

precise clamping

long bore length

unique challenges

several challenges

various industries

cutting parameters

specific challenges

boring inaccuracies

exceptional results

35mm cylinder tubes

Hydraulic Expansion

innovative features

overall productivity

taper-related issues

enhanced productivity

Boring irregularities

operational efficiency

significant challenges

high-volume production

auto clamping mechanism

manufacturing lead time

superior surface finish

uneven material removal

faster material removal

VHM 1000 Honing Machine

advanced honing technology

high-speed honing capability

process taper removal option

35mm Hydraulic Cylinder Tubes

high-quality hydraulic cylinder tubes

efficient material removal capabilities