Honing Machine for Hydraulic cylinder - Achieving the best surface finish for Hydraulic cylinders.

Each industry and company has their own expectation of the surface finish required depending on their application.

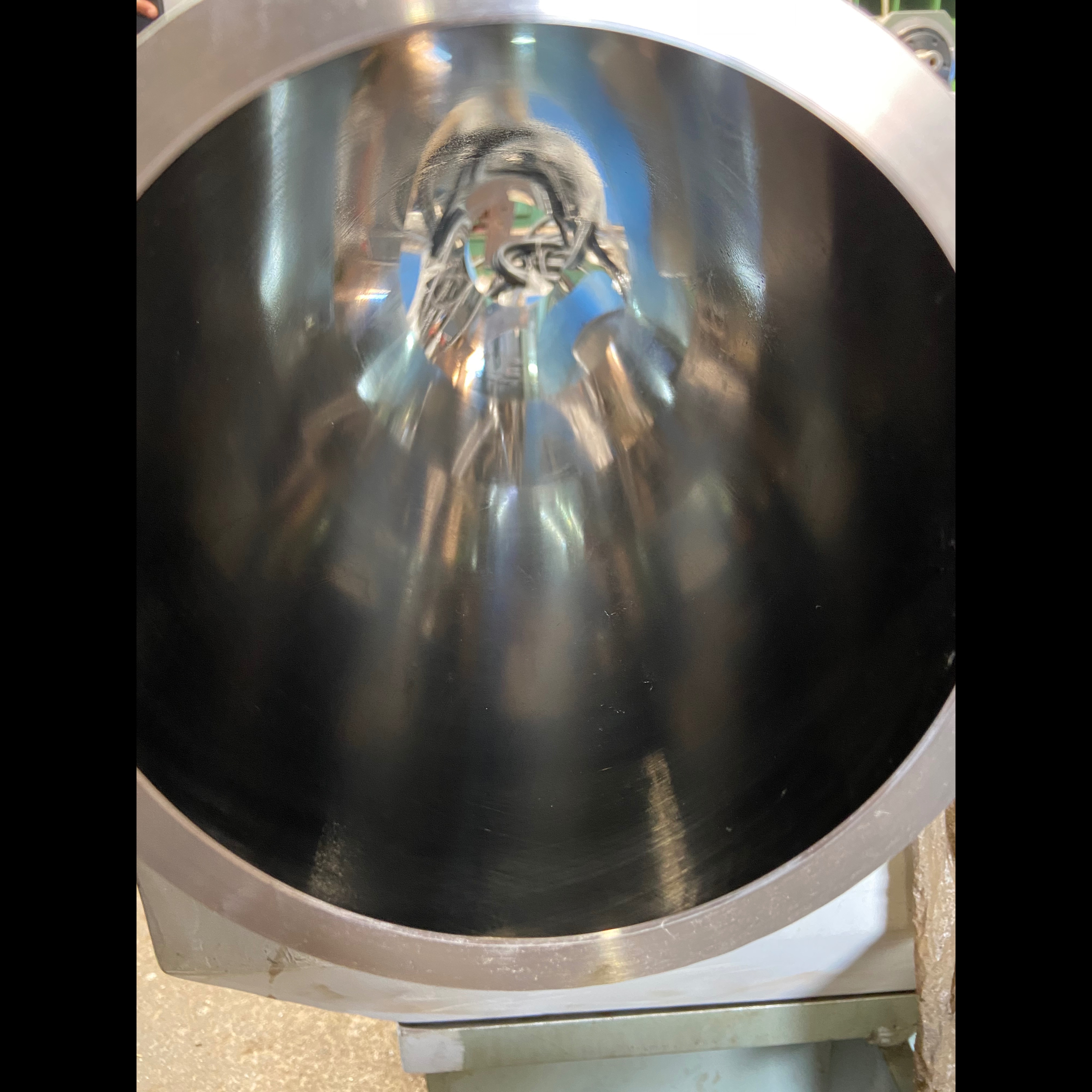

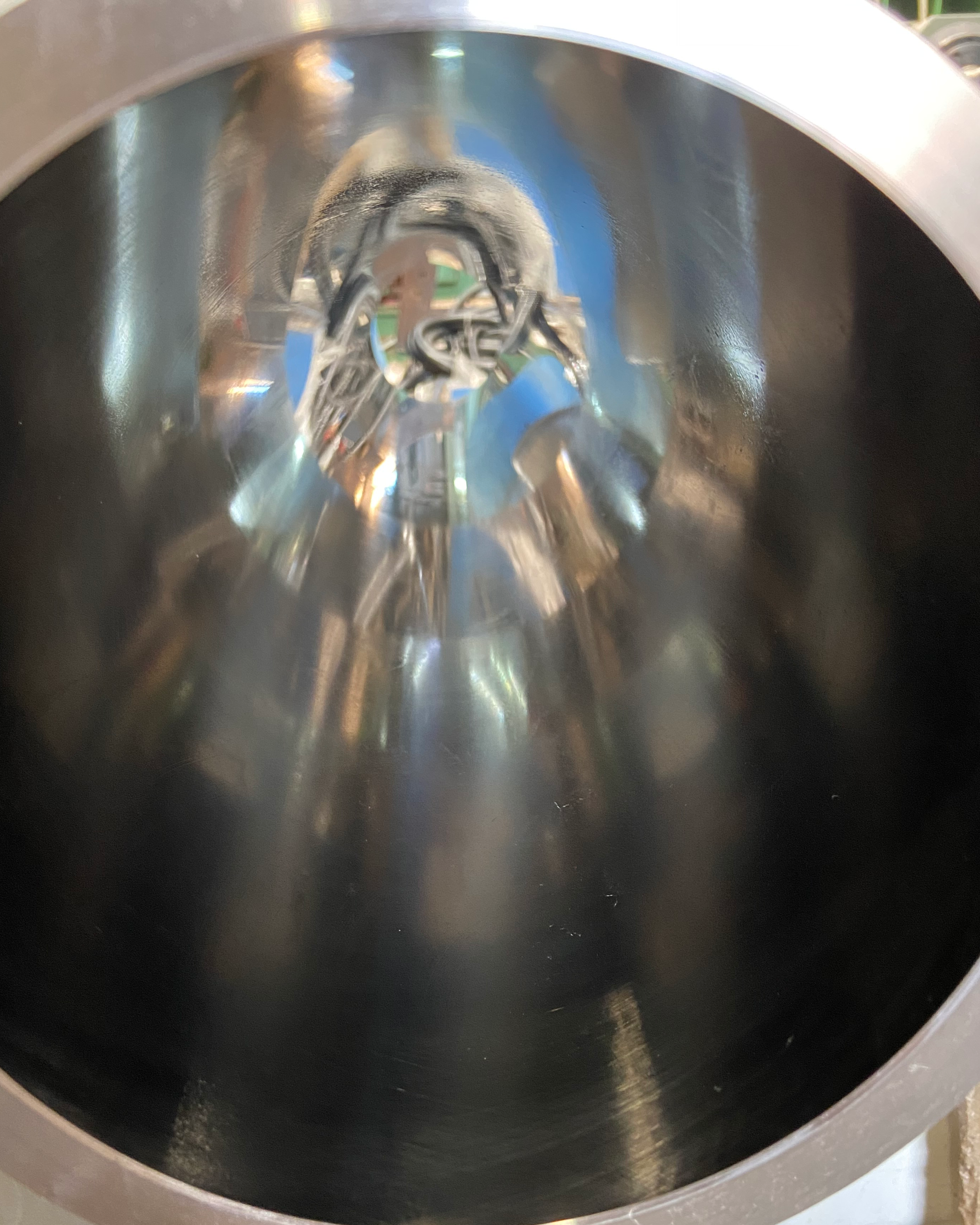

Typically the hydraulic industry asks for 0.2 microns to 0.4microns average roughness , this is again based on the type of seals being used .

We can opt for finer finishes while using PU seals however , when using solid seals and metal seals in special cases, coarser finishes are expected upto 0.4 Microns , where the thin film of oil in the honed surface itself acts as a sealing member allowing the solid seals to slide with very less friction .

Lesser the Friction Higher the seal life and higher the efficiency in hydraulic cylinder operation.

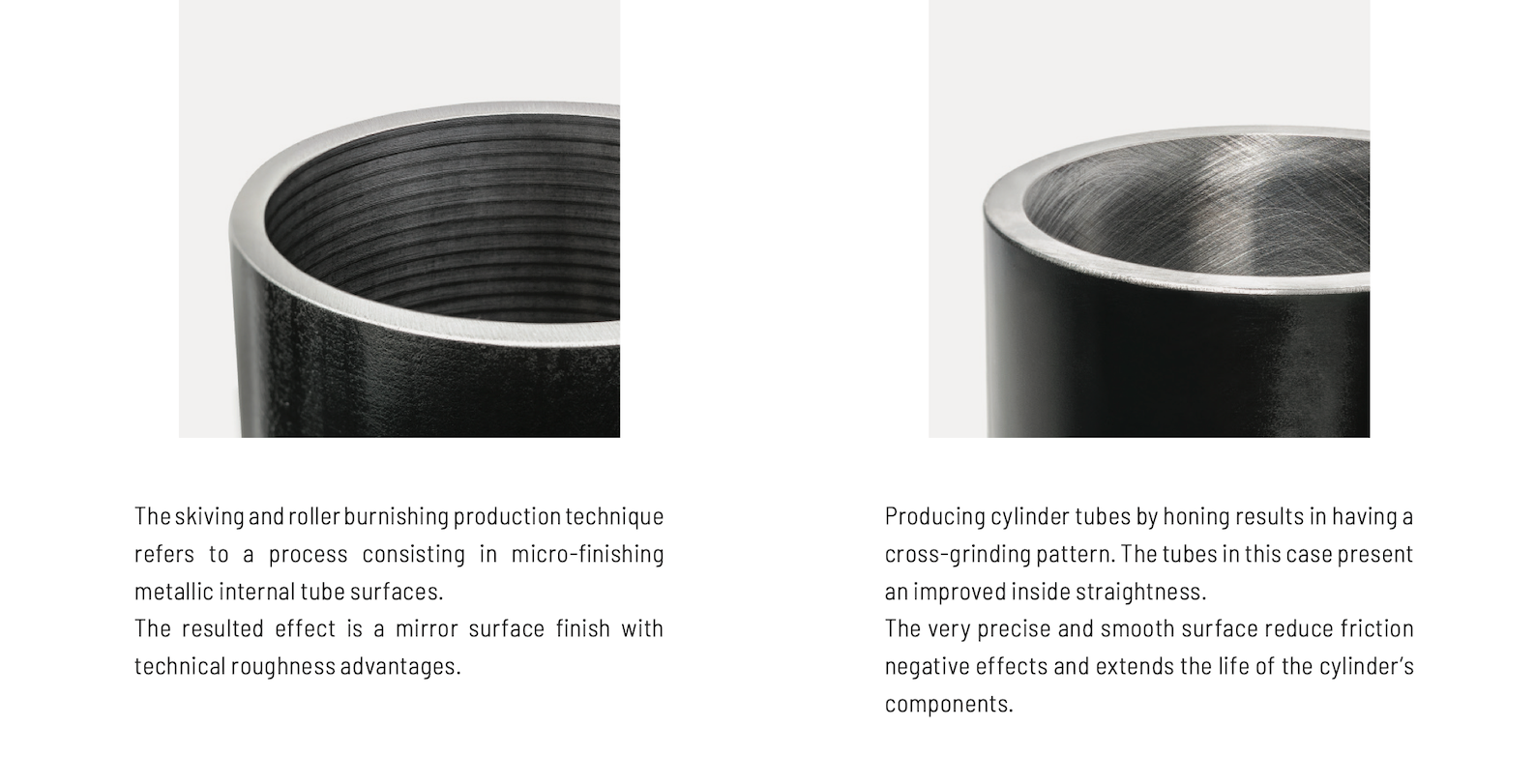

Although there are many alternate methods to enhance surface finish like Burnishing and Grinding and achieve similar Ra values , the cross hatch pattern to hold the oil and allow in the helical movement resulting in the sliding effect is achieved only through honing.

So be it new cylinder or a reconditioned cylinder , always ask was it honed ? What\\\'s the hatch angle ?

Want to know the importance of hatch angle ? its a whole different topic for another blog .

Until then if you want to get in touch with us , feel free to call us .

Regards,

Harikrishna.K.V.

Keywords

02 microns

friction higher

honing machine

metal seals

solid seals

pu seals

feel free

honed whats

sliding effect

alternate methods

seal life

friction lesser

thin film

finer finishes

application typically

reconditioned cylinder

hatch angle

honed surface

hydraulic cylinders

surface finish

hydraulic industry asks

enhance surface finish

hydraulic cylinder operation

hydraulic cylinder achieving

cross hatch pattern

helical movement resulting

sealing member allowing

04microns average roughness